DIRECT CIRCULATION DRILLING

In Difficult Conditions

At Eaton Drilling, we drill boreholes by Direct Circulation when conditions are difficult. Drilling through rock, cobbles and consolidated formations requires specialized drill bits and great downward force. These amendments can be incorporated, when needed, in Direct Circulation drilling. Small diameter boreholes--test holes being the primary application--also complicate drilling when sticky clay formations are encountered. These silty solids can be difficult to extricate through the narrow borehole largely occluded by the drill pipe. Compared to Reverse Circulation methods at the same diameter, Direct Circulation drilling provides greater cross-sectional area for cuttings and drilling fluid to flow through.

Process

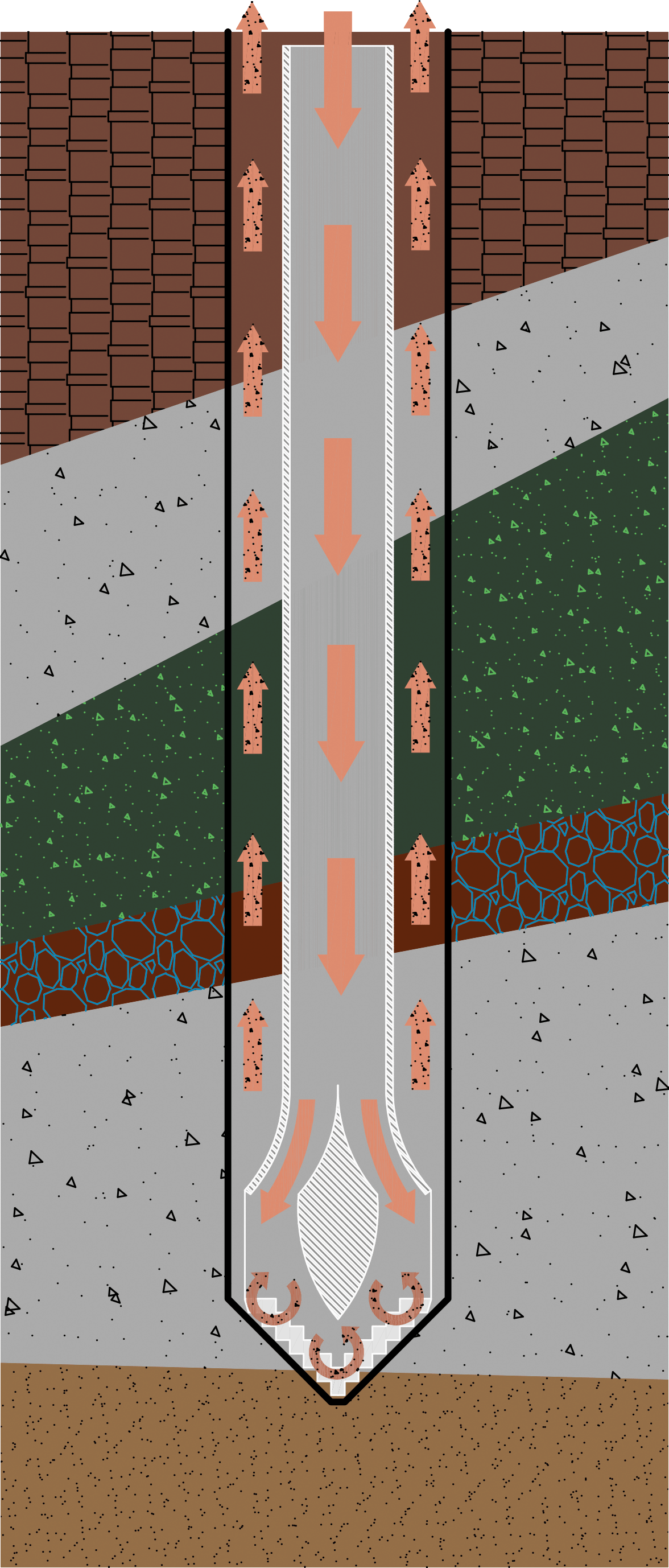

1. Drilling fluid of suitable density and viscosity is pumped down the interior of the drill pipe and exits out of the bit at the bottom of the borehole.

2. Cuttings are suspended in the arriving fluid as it flows into the region of lesser pressure around the exterior of the drill pipe.

3. Mud and cuttings travel all the way up the borehole to the surface where they are then pumped into filtration equipment that separates out the suspended cutting solids (sand, gravel, clay, etc.) from the drilling fluid.

4. The cleaned fluid then travels back to the drilling rig where it is pumped down the drill pipe again in a continual “forward-going” circulation process.

5. As the borehole advances, the specific weight of the drilling fluid must be monitored, and adjusted if necessary, to account for changes in borehole volume, possible influx of water and additional dissolved solids from newly intercepted formations.

Advantages

Direct Circulation drilling accommodates specialized, large diameter drill bits--as well as the tooling used to stabilize them--when drilling through hard, consolidated formations. Typically under these conditions, boreholes are reamed to larger diameters over multiple passes using progressively wider drill bits. Reaming outward, starting from a small diameter borehole, is not an option in Reverse Circulation drilling as small diameter bits, less than 15”, are incompatible—the drill pipe must be wide enough to permit good mud flow through its interior.

Eaton Drilling uses custom mud filtration equipment to perform Direct Circulation drilling. Our “mud shakers” enable rapid and precise control of the composition of drilling fluid at all times. Not only is this ideal for collecting samples of cutting solids during test drilling, but also allows drillers to reduce the specific weight of the borehole fluid prior to inserting the gravel pack during construction of a cased well.

Eaton Drilling Co LLC in Woodland, Contractor license (133783), A General Contractor, C-57 Well Drilling and C-61 Specialty services in California, also other trades Nevada and Oregon. Our equipment conforms to current air quality standards.

Address: 20 West Kentucky Ave, Woodland Ca 95695/ PH: 530.662.6795