PUMP EFFICIENCY TESTING

What is Pump Efficiency?

Pump efficiency is defined as the ratio of water horsepower output from the pump to the shaft horsepower input for the pump. Water horsepower is determined by the flow rate and pressure delivered from the pump. The shaft horsepower is delivered to the pump from the power unit, which usually is an electric motor or internal combustion engine.

How Pump Efficiency is determined

Efficiency = 100 x Power Output / Power Input

Why Pump Efficiency Is Important

Very simple, energy costs money. The less energy you use, the lower your pumping costs will be. By incorporating pump efficiency testing as a component of pump and well maintenance program a data base line in developed. Evaluation and comparison of pump efficiency data on an incremental basis accurately quantifies pump and well performance and efficiency changes. When production requirements are factored in; the pump / well owner has confidence that informed decisions are made in scheduling well and pump rehabilitation and equipment rebuilding.

Pumping time and costs are reduced when diminished pump equipment and well performance is identified by pump efficiency testing and corrected before the off-season.

Older water wells with encrustation blocking perforations and gravel packs, results in declining pumping levels. Pump efficiency testing will identify wells that will benefit from well rehabilitation thus reducing pumping level drawdown, and energy costs.

What Is Measured In A Pump Efficiency Test

Water flow rate, Pumping lift (or inlet pressure), Pump discharge pressure; and Energy input to the pumping plant Calculations are preformed with the flow, lift, and pressure measurements and the results are compared to the energy input.

Useful Well efficiency terms

The following explanations can give you a better idea of what is measured and calculated:

1. Standing Water Level - The water level in the well when a pump has not been running.

2. Recovered Water Level - The water level in the well 10 minutes after shutting off the pump.

3. Draw Down - The difference between the pumping water level and the standing water level.

4. Pumping Water Level - Where the water level in the well stabilizes under constant pumping conditions.

5. Discharge Pressure at Gauge - The pressure on the outlet side of the pump.

6. Total Lift - Includes the pumping water level, discharge pressure, and any gauge corrections.

7. Flow Velocity - How fast the water is moving in the discharge pipe. It should be 1 foot per second or faster to ensure an accurate test.

8. Measured Flow Rate (gpm) - The flow rate measured in gallons per minute using the tester's instruments.

9. Customer Flow Rate (gpm) - The flow rate measured with the customer's flow meter (if one is present).

10. Well Specific Capacity - The measured flow rate divided by the draw down. It is a measure of well performance, not pump performance.*

11. Acre-Feet per 24 Hours - The number of acre-feet pumped in 24 hours at the measured flow rate. One acre-foot of water is equal to 325,851 gallons of water.

12. Cubic Feet per Second (cfs) - The measured flow rate expressed as cubic feet of water per second.

13. Horsepower Input to Motor - The horsepower input to the motor read at the utility meter.

14. Percent of Rated Motor Load - The estimated horsepower output of the motor divided by the name plate horsepower. If this is not between 80% and 115% it is an indication that the motor is not matched to the pumping condition.

15. Kilowatt Input to Motor - The power input to the motor in terms of kilowatts.One horsepower is equal to 0.746 kilowatts.

16. Kilowatt-hours per Acre-Foot - The amount of kilowatt-hours required to pump an acre-foot of water at the operating condition measured.

17. Cost to Pump an Acre-Foot - Kilowatt-hours per acre-foot multiplied by the Base Cost per kWh.

18. Energy Cost ($/hour) - The cost per hour to run the pump at the Base Cost per kWh.

19. Base Cost per kWh - The average cost of a kilowatt-hour for this account.

20. Name Plate rpm - The rated speed of the motor.

21. Measured rpm - The actual rotational speed measured.

22. Overall Plant Efficiency - The power output of the pump (a function of the flow rate and total lift) divided by the input power.**

* Well-specific capacity is a complex relationship based on the aquifer conditions, well casing diameter, well screen, gravel pack selection, and the initial development. For example, high specific capacity wells in the San Joaquin Valley have specific capacity greater than 100 gpm per foot of draw down. Good wells are between 50 to 100 gpm per foot. Low specific capacity of 5 to 20 gpm per foot may be typical for your area or may indicate a problem.Well performance will generally degrade with time. Well screens can corrode or encrust with various deposits that reduce flow openings into the well. Gravel packs can also experience plugging from fine materials such as silt. Attempting to pump too much water by using too big a pump for the aquifer also results in low well specific capacity. This subject is very important to your pumping costs. Consult with Eaton Pumps if the pump test history reveals significant reductions in well specific capacity over time.

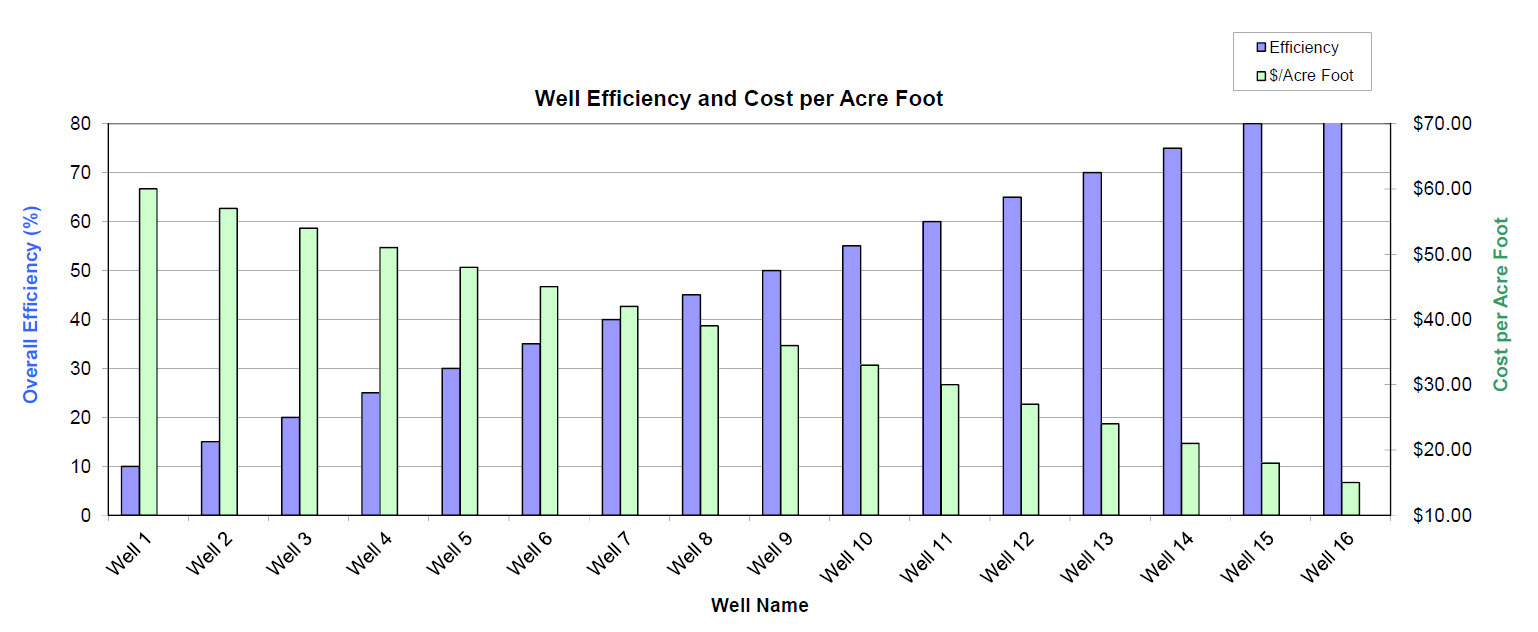

**Overall plant efficiency can be generally characterized as follows:

• 60% and higher is excellent.

• 50% to 60% is good.

• 49% or less indicates a pump that may need a retrofit,repair, or adjustment. It also may indicate the pump is not matched to the current required operating conditions. An example of this would be where a water table has dropped substantially over time, increasing the total lift above the original specifications.

Pumps with submersible motors will usually run about 10% lower efficiency in each of the categories above. For example 50% or above would be considered excellent for a submersible pump.

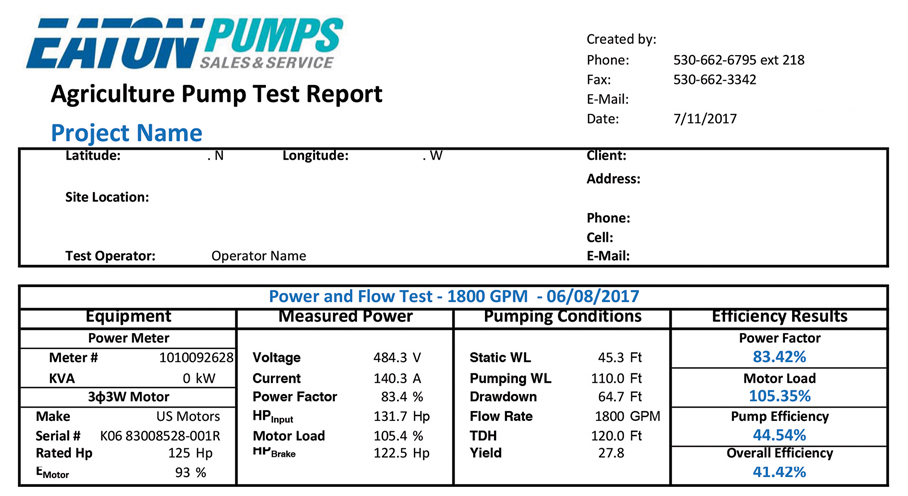

Pump Efficiency Test Form

Let us know your questions, suggestions and concerns by filling out the contact form below.

Eaton Drilling Co LLC in Woodland, Contractor license (133783), A General Contractor, C-57 Well Drilling and C-61 Specialty services in California, also other trades Nevada and Oregon. Our equipment conforms to current air quality standards.

Address: 20 West Kentucky Ave, Woodland Ca 95695/ PH: 530.662.6795